Warehouse managers are a vital part of the supply chain process, overseeing and managing people, processes and systems in order to keep the warehouse running effectively.

To help ensure warehouse tasks are carried out as efficiently as possible, we’ve created a toolbox of useful guides, checklists, tools and resources for warehouse managers covering some of the most commonly encountered problems when it comes to racking and storage in the warehouse.”

Please feel free to download, print and share any of our resources as you see fit, if you require further assistance contact us in confidence by calling 0117 955 5211 or emailing [email protected].

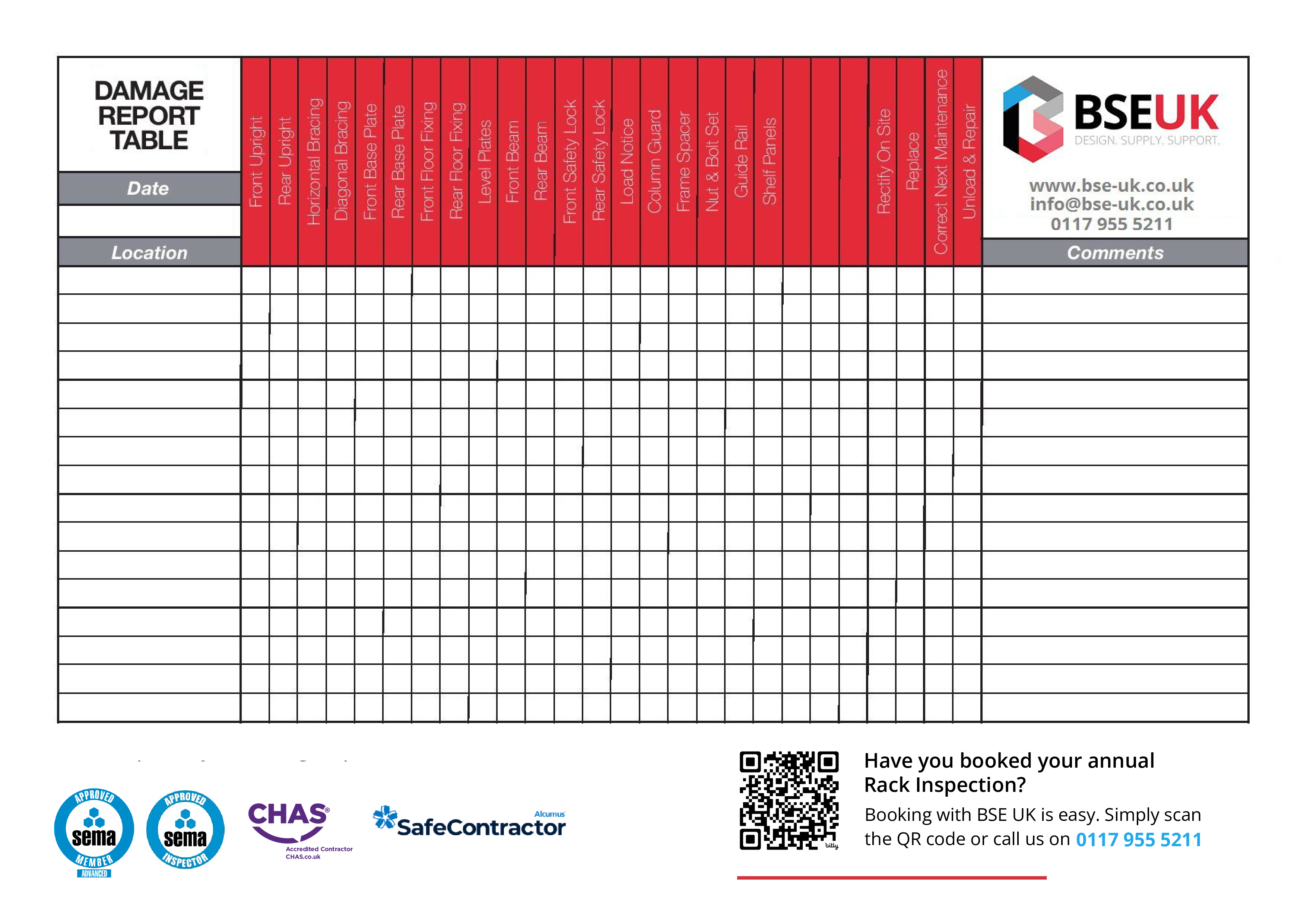

Rack Inspection Checklist

As a warehouse manager, you are responsible for ensuring a safe working environment for employees. Pallet racking is defined as ‘work equipment’ meaning it must be safe and compliant with Health and Safety legislation.

As well as annual SEMA racking inspections, on-site visual racking inspections are a crucial part of ensuring your racking is safe. These checks take very little time and can be crucial in identifying and repairing damage to your system that could lead to eventual system failure.

To help ensure these crucial checks don’t get missed, we’ve created a rack inspection checklist to help you keep track of inspections and monitor any damage to your pallet racking system.

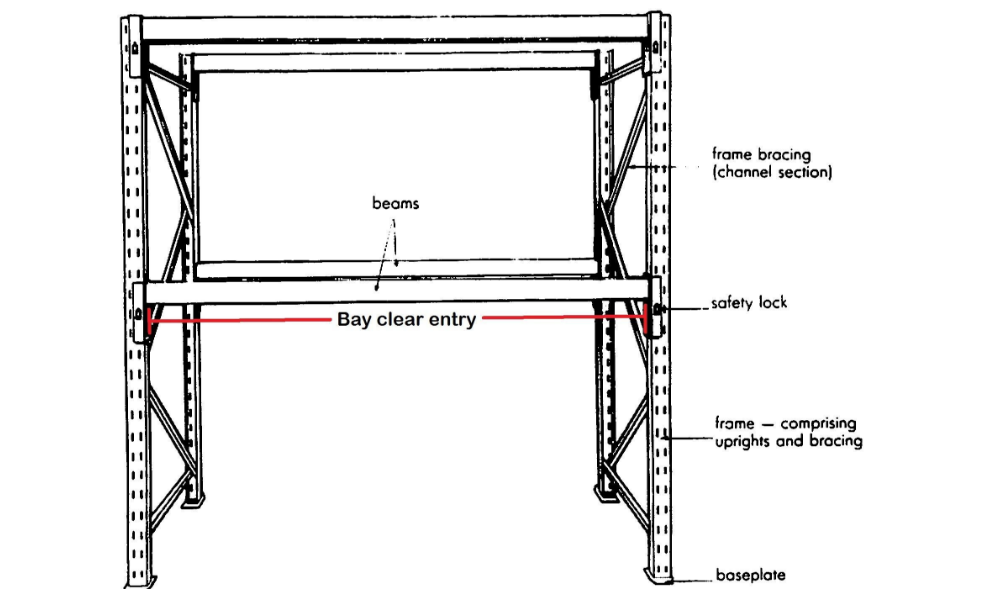

Pallet Racking Weight Limits Guide

One of the most common questions we’re asked is ‘how much can my racking take’ and it’s an important question. Overloading your racking can result in damage and even system collapse, underloading your racking results in reduced overall efficiency of the system.

To help you, we’ve written a blog post detailing all the measurements you’ll need to calculate your weight limit.

Racking Identification Tool

With so many different racking brands available to warehouses, it can be difficult to identify which particular brand or model yours is. The danger here is that it can make identifying common problems, calculating weight limits and understanding what stock your racking can take much more difficult.

We’ve created a useful racking identification tool to help you with this issue, covering leading brands such as Dexion, Link 51, Hilo and PSS; we’ve also included some uncommon types of racking to help you identify your system if it’s old or even phased out.

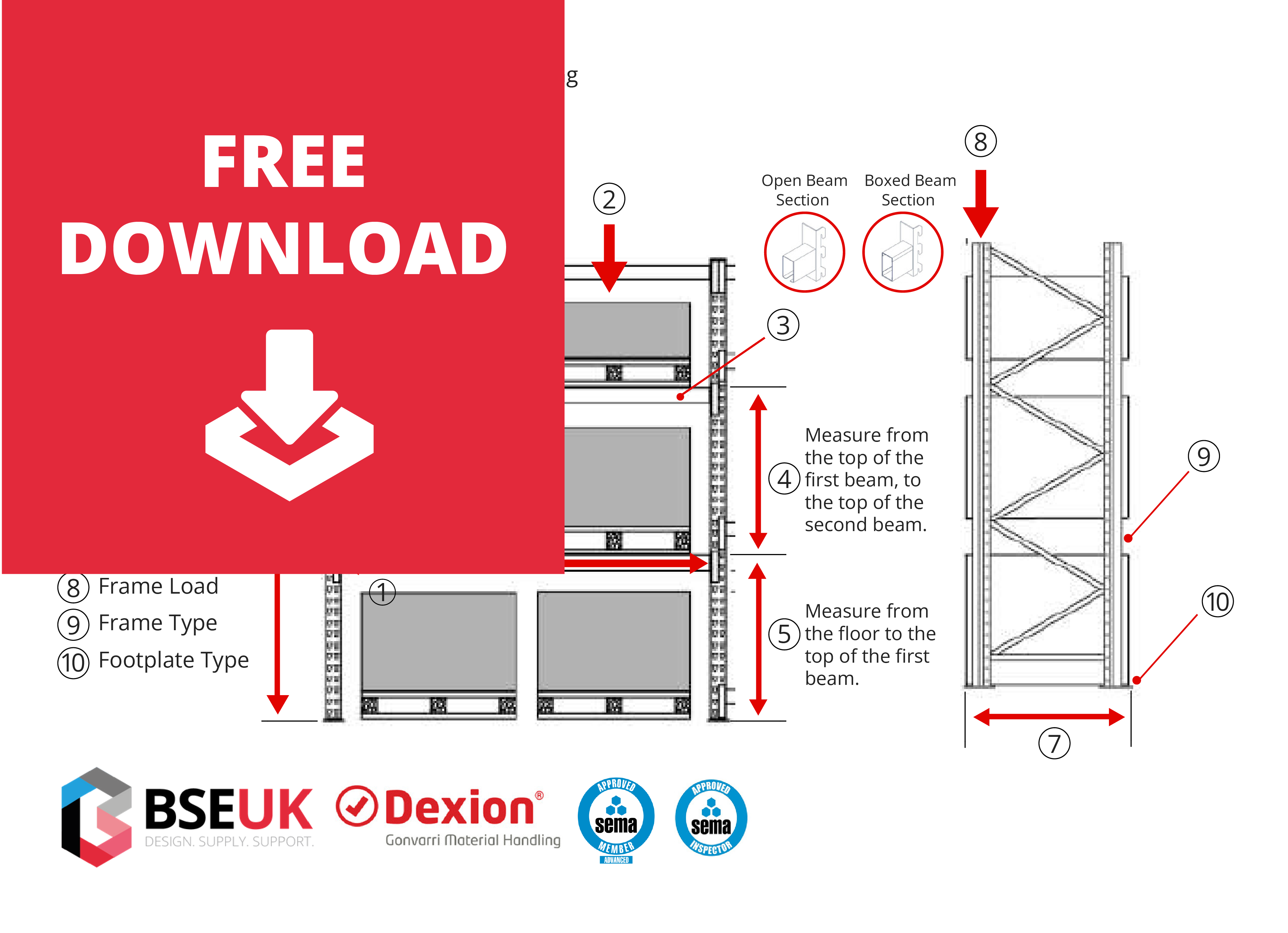

Design Elements Tool

Without the right measurements, quotations for racking systems are less accurate and can take longer. It could also be the case that without leaving the right clearance or overhang during measurements your figures will be wrong, compromising the design you had planned.

To ensure you always have the right measurements to hand for a fast and accurate quotation, we’ve created a design elements tool detailing all the measurements you will need, along with tips from our expert team for ensuring your measurement taking is accurate.

Mezzanine Floor Building Regulations

A mezzanine flooring system is an effective way of using up unused overhead space in the warehouse, whether that be for office or storage use. Something we are so often asked by warehouse managers during these projects is, “do I need planning permission?”.

Like most large builds, there are a number of often complex and misunderstood permissions, regulations and laws that need to be adhered to in order to erect a mezzanine flooring system.

Our blog post details all you need to know about building a mezzanine flooring system including, planning permission, building regulations requirements, structural safety, fire safety and more.

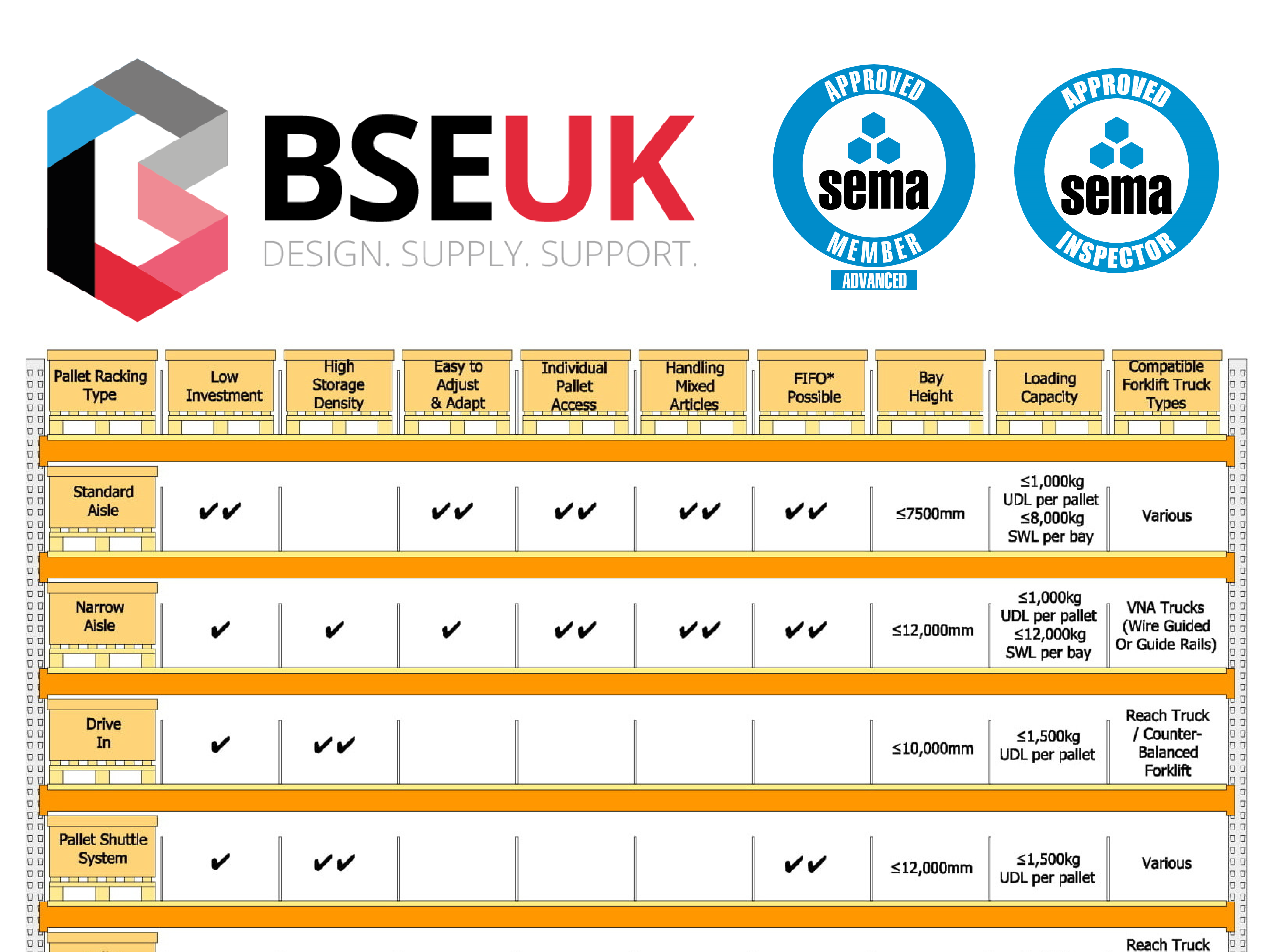

What Pallet Racking Should You Get?

With so many different options available, deciding what type of pallet racking best suits your operation can be a confusing process, but it’s such an important one. Installing a system that’s not the right size, type or fit for your warehouse can result in an inefficient system.

From standard aisle racking to pallet flow, our pallet racking chart runs through all the different types of pallet racking and their uses including loading capacity, bay height, cost and more to ensure you choose the right fit for your needs.

A-Z Warehouse Terms Jargon Buster

Warehousing is full of jargon. As a warehouse manager, you need to ensure that not only you, but also all your members of staff can understand the jargon they may hear on a daily basis.

From adjustable pallet racking to zone picking, our jargon buster covers all the essential terms you need to be familiar with in the warehouse.

2022 Store Catalogue

Our 2022 store catalogue is here!

Click the button below to browse through our extensive range of products including racking, shelving, and storage bins.

We trust you have found these Warehouse Manager resources to be of use but if you have any questions about them or any other aspect of your warehouse racking please contact us here or by phone on 0117 955 5211, we’re happy to help.