When Standard Pallet Racking Isn’t Enough: Moving to Heavy Duty Racking Systems

In most warehouses, change happens gradually. Pallet weights increase, product ranges evolve, and throughput grows, until the racking that used to work just doesn’t meet the operation’s needs.

For UK warehouse managers and business owners, this is when questions arise: Can the existing pallet racking system safely handle current loads? Is it limiting storage heights, workflow, or speed? A heavy duty racking system becomes a practical consideration, not as an upgrade, but as a way to remove constraints and reduce risk.

What standard pallet racking is designed to handle

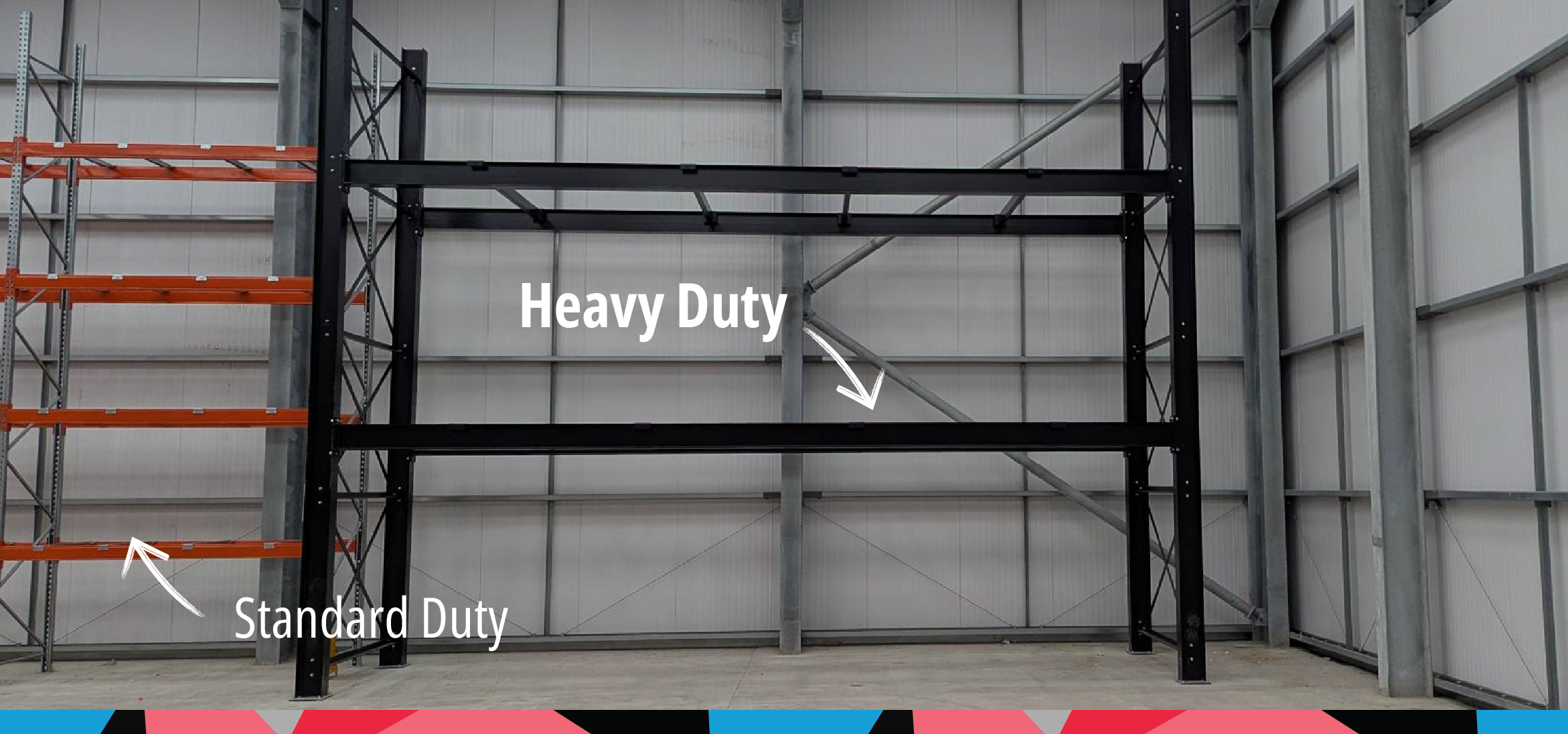

Standard pallet racking works well as a warehouse storage solution for many, offering flexibility and straightforward installation. But it’s built around specific load assumptions, supporting pallet weights between 500kg and 1,000kg when loads are evenly distributed.

Pallet racking beam and upright profiles are usually smaller box-section designs, with most standard systems engineered to support up to 4 tonnes per level. If these limits are exceeded, upgrading to I-section beams and uprights is needed, which form the structural foundation of a heavy duty pallet racking system.

As pallet weights increase, storage heights grow, or layouts evolve, standard racking can start to create operational bottlenecks, higher maintenance demands, and increased safety risks.

Signs standard racking isn’t enough

The need for a racking upgrade is usually clear once the system is properly assessed. Changes in load, handling, and routine operations, combined with rack inspection findings, quickly show when standard racking is no longer suitable. When capacity limits or safety margins are being approached or exceeded, the impact is felt across the warehouse. Signs include:

- Operational limitations and workarounds: Heavier pallets may be restricted to certain bays or lower levels, or stock manually redistributed. These adjustments reduce flexibility and slow replenishment.

- Repeated damage and inspection findings: Beams deflect under load, but exceeding the manufacturer’s safe deflection limit requires immediate pallet removal. Uprights may buckle or twist, and floor fixings can loosen. These are commonly identified in rack inspections, highlighting the importance of routine checks.

- Downtime and workflow impact: Frequent rack repairs or inspections disrupt picking and storage, slowing operations and adding pressure to schedules.

Operational risks of under-specified racking

Overloading racking increases safety and operational risk:

- Reduced structural safety margins: Loading near maximum capacity leaves little tolerance for error. Minor issues like unsafe pallet loading or uneven weight distribution can cause point loading issues, beam deflection beyond safe limits, or upright buckling.

- Higher maintenance and inspection overhead: Overstressed racking generates frequent repair needs, increasing downtime and maintenance costs, and raising compliance risks with insurers and the HSE.

- Constraints on growth and automation: Under-specified racking limits layout changes, higher stacking, and automation like shuttle systems or high-reach forklifts. Essentially, it locks the warehouse into its current configuration.

For detailed industry guidance on pallet racking safety terminology, load notices, inspection standards and best practice, take a look at SEMA Pallet Racking Safety Technical Bulletins from the Storage Equipment Manufacturers’ Association.

How heavy duty racking systems differ

A heavy duty racking system is engineered to withstand heavy industrial use that places significant strain on standard racking. They remain structurally sound when handling heavier pallet loads, frequent forklift activity, and higher storage heights, resulting in far fewer issues being identified during routine inspections and reducing the need for corrective actions.

Heavy duty components also ensure this type of system is more resilient to daily wear and tear, helping floor fixings, uprights, and beams stay secure and reducing downtime. Like standard duty pallet racking, the modular structure allows flexibility with warehouse layouts, including higher density storage with narrow aisles, automation and maximising headroom space with additional levels are greater heights - without compromising safety.

As a result, teams can work with greater confidence, knowing the racking is fit for purpose, and therefore supporting throughput targets without constant disruption to daily operations.

Operational factors driving the move to heavy duty racking

Some warehouse changes highlight the need for a heavy duty pallet racking system:

- Increased pallet weights

- Denser loads

- Changes to forklift type or reach height

- Higher stacking heights

- Increased throughput and traffic

Factors beyond load capacity

Stronger racking alone isn’t enough - several operational factors must be considered:

- Floor bearing condition: Ensure the floor can support increased point loads.

- Aisle widths and truck selection: Heavier racking may influence aisle layouts and equipment choice - for example, a Very Narrow Aisle set up may not suit heavy dusty pallet racking systems due to the load bearing of the specialist forklift trucks required.

- Future flexibility and expansion: Design should allow layout changes without a full redesign.

- Compliance: Follow SEMA guidance by ensuring regular inspections, routine checks, and any repair work are carried out promptly, and display clear load notices indicating the weight capacities of each rack.

Planning the transition to heavy duty racking

Upgrading to heavy duty pallet racking doesn’t have to be disruptive if approached in the right way. The first step is to assess current and future load profiles by understanding load demands to ensure the racking is genuinely fit-for-purpose overtime, and not just sufficient for today’s demands.

This is also an opportunity to re-evaluate layout and warehouse flow. Using the upgrade can support optimisation of picking routes and storage logic. The team here at BSE UK carry out free site visits to measure and discuss layout and technical requirements based on your needs.

Pallet Racking installation can then be phased to work around your daily operations with minimum disruption, whether by working in phases to maintain operations and minimise disruption, or installing all in one go. As part of our advanced SEMA membership requirements, our expert pallet racking consultants design with both rack safety and warehouse efficiency in mind, so that it performs as intended to enable ongoing compliance.

For growing UK businesses, a heavy duty racking system isn’t about complexity - it’s about giving warehouse operations the capacity, resilience, and reliability to handle daily pressures safely and efficiently.

Ready to Upgrade to a Heavy Duty Racking System?

If your warehouse is showing signs that standard pallet racking isn’t keeping up with your operational demands, it’s time to take action. At BSE UK, we help growing businesses across the UK assess, plan, and install heavy duty racking systems safely and efficiently.

We offer a free site visit to review your current racking, check load capacities, and discuss the best heavy duty solution for your warehouse. Our team will provide expert recommendations, fully aligned with SEMA guidance and best practice, so you can operate with confidence.

Contact us today:

Phone: 0117 955 5211

Email: [email protected]