Cold Storage Best Practice Guide – Tips on Racking for Cold Rooms

Best Practice Guide to Cold Storage Racking – Get some Great Tips!

How To Maximise Space In Your Warehouse Without Expanding

Effective cold storage is crucial for maintaining the quality and shelf life of stock that must be kept at a specific temperature, this often includes perishable food and drink and medicines.

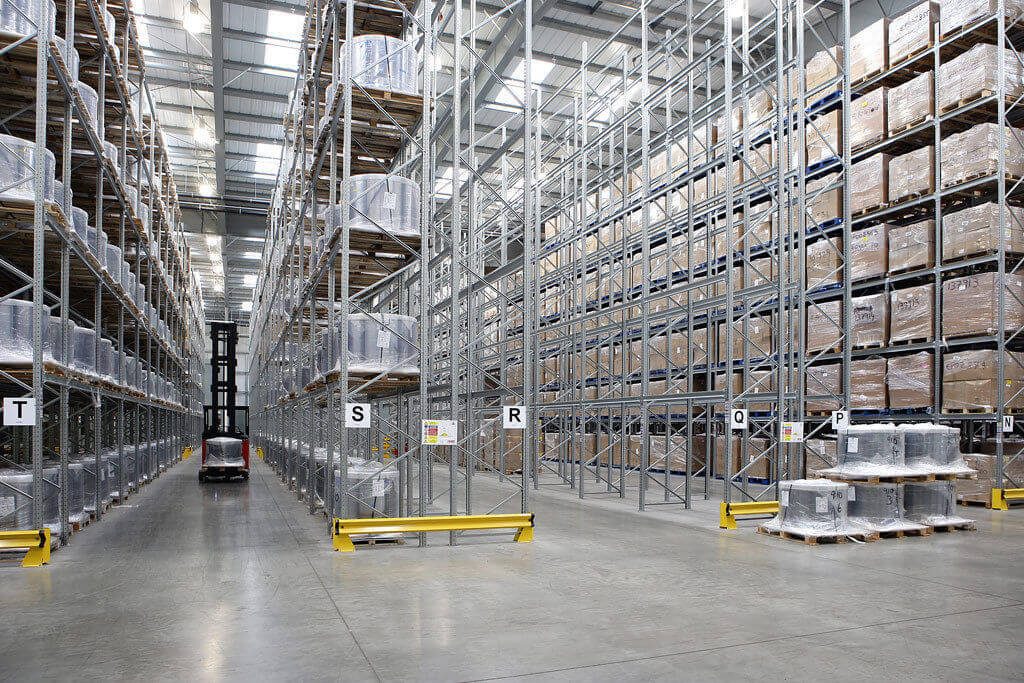

The choice of racking or shelving used in cold storage is an important one. Using the right storage solution can not only help to maximise the precious space in your cold storage areas, but can also prevent damage to stock and ensure temperature uniformity.

In this blog post, we will explore the best types of racking and shelving suitable for cold storage areas and provide insight into how you can ensure your cold items are stored properly.

What Is Cold Storage?

Cold storage areas are classified based on the temperature inside the storage area. Refrigerated storage areas maintain temperatures between 0-5ºC, suitable for storing perishable items. On the other hand, freezing environments, have temperatures of 0ºC or below.

Stock Held in Cold Storage Areas

Cold storage areas are used for a wide range of products that would spoil or have a reduced shelf life without special temperature-controlled storage areas. Items typically held in these environments include:

- Food and drink including fruits, vegetables, dairy products and meat. These are often stored before being shipped to the supermarkets, so its imperative that they remain chilled to improve shelf life.

- Medicines that need to be kept at a specific temperature to remain effective.

In addition to preventing spoilage, regulation around the storage of specific items also exists and so cold storage areas are essential to comply with these regulations.

Cold Storage Racking and Shelving Types

Many different racking and shelving solutions are available for cold storage. Some of the most common types of racking and shelving systems used include:

- Adjustable Pallet Racking – Adjustable racking is highly versatile and can accommodate various pallet sizes. It offers different aisle options (narrow and wide) and can be adjusted as needed. APR can also be quickly assembled and disassembled making it ideal for operations with changing needs.

- Chrome Wire Shelving – Chrome wire shelving is a cost effective shelving system that is suitable for temperatures down to -28ºC. The unit is corrosion resistant, hygienic and features antibacterial protection making it the ideal choice for storing food and drink.

- Pallet Shuttle – Pallet shuttles are semi automated racking systems which enable high density storage. The compact nature of the system also maximises available space making it ideal for cold storage environments. The system can also operate fully at very low temperatures.

- Drive-In Racking - Drive-in racking is another high-density solution suitable for storing larger, bulkier goods on single SKU pallets. Drive-in systems are particularly effective when storing products with a long shelf life in cold storage.

Proper Storage Practices for Cold Areas

In cold storage environments, proper storage of stock is critical to success. Not only can poor storage practices waste this valuable cold storage space, but it can also result in spoilage of stock which means loss of revenue.

Our top storage tips for cold areas include:

- Segment and categorise items to prevent cross-contamination and improve organisation.

- Label items with their storage requirements and expiry date.

- Monitor temperatures regularly within your cold room to ensure a consistent temperature is maintained.

- Adhere to a storage principle based on the type of stock you are storing. For example, First In, First Out (FIFO) is appropriate for items with a shorter shelf life.

- Keep the racking or shelving clean and free from debris to prevent contamination and ensure uniformity of temperature.

- Ensure that you are not overloading your racking or shelving. This can result in damage to the system and may mean that your products are not kept at the correct temperature due to reduced airflow.

- Ensure that your cold storage racking undergoes routine racking inspections to reduce the risk of damage and collapse.

Experts In Cold Storage Racking and Shelving

Choosing the right racking and shelving for your cold storage area is important for preserving the quality and extending the shelf life of perishable goods, as well as maximising the space you have available in cold storage areas.

At BSE UK, we help businesses make the right choices when it comes to cold storage solutions; taking time to understand their needs and storage requirements before recommending the best solution for their unique needs.

With over 50 years experience in the industry, we provide an all encompassing service including design, installation and ongoing care of racking and shelving products, meaning you’ll only have to deal with one supplier throughout.

For more information, give us a call today on 0117 955 5211 or book a free site survey and one of our expert team will visit your premises to assess your needs.

Contact us

Bristol Storage Equipment Limited

Unit 2, Severnlink Distribution Centre,

Chepstow, NP16 6UN

Sign up to receive our newsletter

By submitting this form you agree to our privacy and data protection policy which governs how we deal with personal data.